In recent years, there has been growing concern about the environmental impact of electronic waste, or e-waste, which includes discarded electronic devices such as computers, smartphones, and televisions. E-waste often contains valuable metals like gold, silver, copper, and palladium, but it also contains toxic heavy metals such as lead, cadmium, and mercury. Proper disposal and recycling of e-waste are crucial to minimize the negative effects on the environment and human health.

Electronic waste or E-waste refers to the discarded electrical or electronic devices which have neared their useful life. Because of the toxicity and carcinogenicity of some compounds, the proper management and safe disposal of these electronic wastes have become serious challenges in recent years.

The E-waste also comprises of metals having economic value which needs to be extracted to before disposing them. Researcher across the world are working on various cost effective methods to extract the value out of the E-waste in environmentally safe manner.

One promising approach to extracting metals from e-waste is through a process known as bioleaching, which involves the use of living organisms, specifically bacteria and fungi. These microorganisms have the ability to break down and dissolve metals from solid materials, including electronic waste.

The bioleaching process typically involves exposing the e-waste to the microbial culture in a controlled environment. The microorganisms break down the complex electronic waste, releasing organic acids, enzymes, and other compounds that facilitate metal leaching. The dissolved metals can then be separated from the solution using various techniques such as precipitation, solvent extraction, or electrowinning, depending on the specific metal and desired outcome.

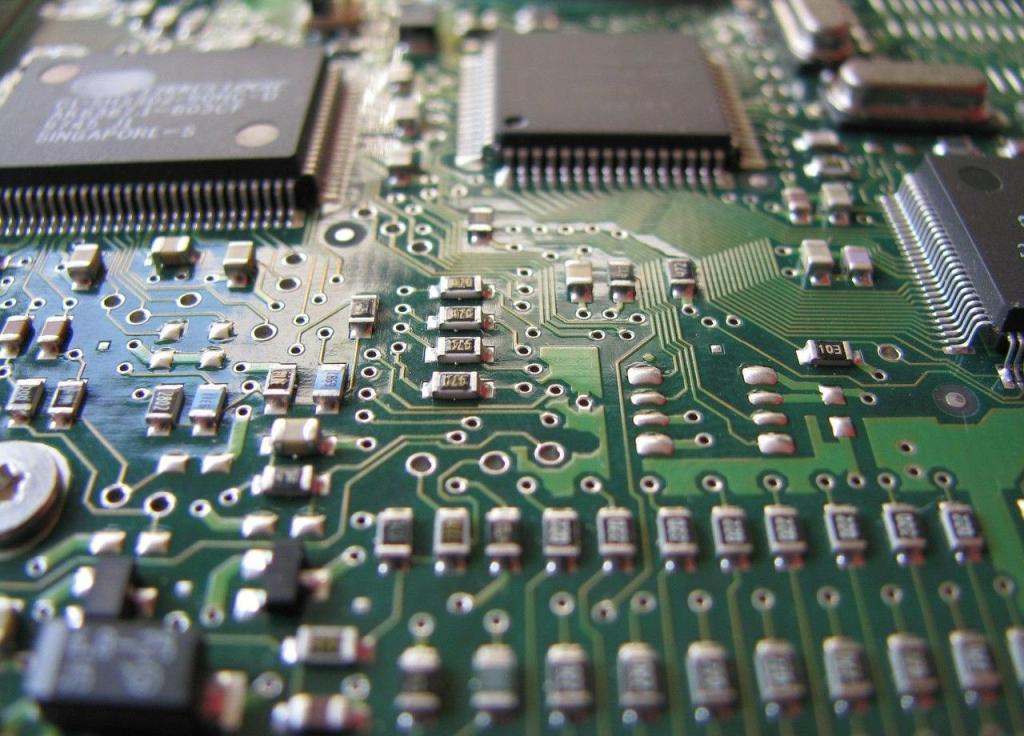

In a recent published study, bioleaching of metals from Printed Circuit Boards (PCBs) using bacterial and yeast strains (Stenotrophomonas maltophilia, Bacillus sp. and Candida tropicalis) isolated from heavily contaminated soil samples was successfully tested.

Printed Circuit Boards (PCBs) are used in almost all electronic devices which may contain up to 60 different chemical elements and have a metal content as high as 40% by weight. The PCBs are a complex mixture of materials such as plastics (13%), glass ceramics (24%), and metals (64%) including precious metals such as silver (Ag), gold (Au), and palladium (Pd), base metals such as copper (Cu), aluminium (Al), nickel (Ni), tin (Sn), silicon (Si), indium (In) and toxic metals such as cadmium (Cd), lead (Pb), arsenic (As), mercury (Hg), and bromine (Br). Hence, recovery of metals from the Printed Circuit Board is profitable, since these PCBs are used in almost every electronic gadget due to their high availability.

In the study a two-step bioleaching procedure was followed for maximum mobilization of metals. The isolated strains were able to mobilize metals from PCBs with different efficiencies depending on their ability to utilize the E-waste a carbon source when cultivated in minimal media. Bioleaching potential of isolated microbes on eight heavy metals (Cu, Ni, Mn, Pb, Fe, Cr, Zn & Co) in the sample were studied using AAS and SEM analysis before and after the two-step bioleaching process and found to be efficient.

Bioleaching is the extraction of metals from their ores through the use of living organisms. This is much cleaner than the traditional heap leaching using cyanide. Bioleaching is one of several applications within biohydrometallurgy and several methods are used to recover copper, zinc, lead, arsenic, antimony, nickel, molybdenum, gold, silver, and cobalt.

The findings of the study revealed that microbes can play an important role in metal recovery. The metal concentrations were drastically reduced from their initial concentration because of the detoxification process and metabolic activity of microbial isolates.

According to the researchers the efficacy of leaching activity can be further improved by using a consortium of microbes which can be used as an efficient source in the removal of metals from discarded PCBs in an economic and eco-friendly way.

Bioleaching offers several advantages over traditional methods of metal extraction from e-waste. It is a relatively low-cost and environmentally friendly approach that can be conducted at ambient temperatures and pressures, reducing energy consumption and greenhouse gas emissions. Furthermore, bioleaching can selectively target specific metals, allowing for more efficient and targeted metal recovery.

However, it is important to note that bioleaching is still an emerging technology and there are challenges to overcome. Factors such as the type of e-waste, microbial culture selection, and optimization of process conditions need further research and development. Additionally, the presence of toxic elements in e-waste requires careful handling and proper waste management to prevent environmental contamination.

For the full research paper visit: 10.46488/NEPT.2022.v21i02.018

Subscribe

Subscribe to our newsletter

Follow us on twitter @DecodingBiosph1