In our daily lives, we encounter aluminum in various forms, from soda cans to kitchen foil. But have you ever wondered what happens to these aluminum items after you toss them into the recycling bin? Let us explore more about recycling aluminum, from collection to transformation, and see how this common metal can make a significant difference for our environment.

The Aluminum Advantage

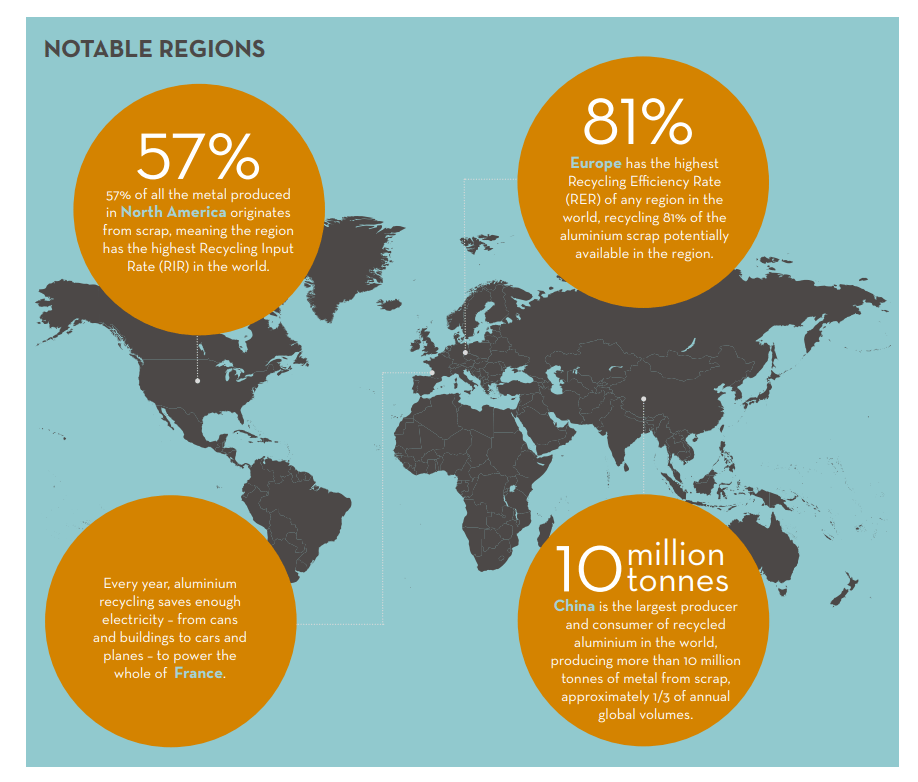

Before we look into the recycling process, let’s understand why aluminum is such a remarkable material. Aluminum possesses a unique set of qualities that make it an environmental hero. Its lightweight nature reduces transportation costs and emissions, while its exceptional durability ensures that it can be recycled repeatedly without losing its integrity. Aluminum’s resistance to corrosion means it can withstand various environments, ensuring longevity in countless applications. Aluminum is one of the most recycled materials globally, with an average recycling rate of approximately 75% for aluminum products.

recycling process of aluminium

Recycling aluminum is a complex and energy-efficient process that transforms used aluminum products into new ones. The recycling process involves several key steps, each contributing to the conservation of resources, energy savings, and reduced environmental impact. Here is a detailed explanation of the aluminum recycling process:

- Step 1: Collection and Sorting

- The recycling journey begins at collection points where consumers and businesses deposit aluminum items into recycling bins.

- Collection trucks transport the recyclables to material recovery facilities (MRFs) or recycling centers.

- At MRFs, the aluminum is sorted from other recyclables like glass, plastic, and paper using conveyor belts, magnets, and eddy current separators.

- Step 2: Cleaning and Preparing

- Once sorted, aluminum items undergo thorough cleaning to remove contaminants such as food residue or labels.

- Shredding machines reduce the aluminum into small, manageable pieces, facilitating the subsequent melting process.

- Step 3: Melting

- Shredded aluminum pieces are loaded into melting furnaces, which operate at high temperatures, typically around 660°C (1220°F).

- The intense heat causes the aluminum to melt, turning it into a liquid state.

- Impurities like coatings and paint burn off, leaving behind pure molten aluminum.

- Step 4: Purification

- To ensure the aluminum’s purity, it may go through a purification process to remove any remaining contaminants or alloying elements.

- Step 5: Casting

- The molten aluminum is then cast into various forms, such as ingots or billets, depending on the intended use.

- For recycling aluminum cans, the molten metal is typically cast into small rectangular blocks known as “pigs.”

- Step 6: Rolling or Extrusion (Optional)

- Depending on the desired end product, the aluminum may undergo additional processes like rolling or extrusion.

- Rolling involves passing the aluminum through rollers to create sheets or foils.

- Extrusion involves forcing the aluminum through a die to produce specific shapes or profiles.

- Step 7: Manufacturing New Products

- Aluminum manufacturers purchase recycled aluminum and use it as a raw material to produce various products.

- Common items made from recycled aluminum include beverage cans, automotive parts, window frames, aircraft components, and more.

- Step 8: Distribution and Use

- The newly manufactured aluminum products are distributed to various industries and consumers for use.

- These products may have a significant percentage of recycled aluminum content, reducing the need for virgin aluminum production.

- Step 9: End of Life

- Eventually, aluminum products reach the end of their useful life and become recyclable materials themselves.

- The recycling process can begin anew, creating a closed-loop system where aluminum is continuously recycled, conserving resources and energy.

Also Read: HOW DOES RECYCLING HELP TO REDUCE POLLUTION

Benefits of recycling aluminum

Recycling aluminum offers a multitude of benefits, ranging from environmental conservation to economic advantages. Here are some of the key benefits of recycling aluminum:

- Energy Savings:

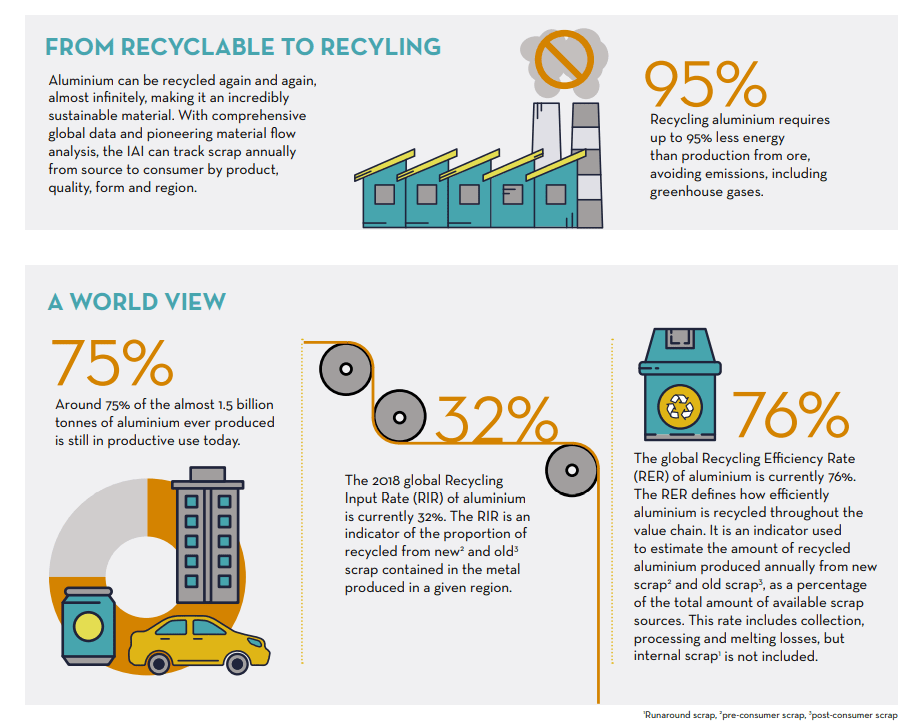

- Recycling aluminum consumes significantly less energy compared to producing aluminum from raw bauxite ore.

- Energy savings can be as high as 95%, making aluminum recycling highly efficient.

- Lower energy consumption reduces greenhouse gas emissions associated with energy production.

- Resource Conservation:

- Aluminum is made from bauxite ore, a finite natural resource. Recycling conserves bauxite reserves for future generations.

- The recycling process requires only 5% of the energy needed to extract and refine bauxite.

- Reduction of Waste:

- Recycling aluminum minimizes the amount of waste sent to landfills or incinerators.

- Reducing landfill waste helps alleviate environmental concerns related to overflowing landfills and soil contamination.

- Lower Greenhouse Gas Emissions:

- Aluminum production is a significant contributor to greenhouse gas emissions, primarily through the extraction and refining of bauxite.

- Recycling aluminum reduces emissions associated with mining, refining, and smelting.

- Recycling a ton of aluminum saves more than 9 metric tons of CO2 emissions.

- Economic Benefits:

- Recycling aluminum generates jobs in collection, sorting, processing, and manufacturing.

- The aluminum recycling industry contributes to the economy through job creation and revenue generation.

- Conservation of Natural Habitats:

- Mining for bauxite ore often leads to habitat destruction and ecosystem disruption.

- Recycling aluminum reduces the need for bauxite mining, helping preserve natural environments.

- Reduced Air and Water Pollution:

- Aluminum production releases pollutants into the air and water, affecting both human health and the environment.

- Recycling mitigates these pollution risks by reducing the demand for primary aluminum production.

- Energy-Efficient Manufacturing:

- Using recycled aluminum as a raw material requires less energy during the manufacturing process.

- Recycled aluminum products maintain the same quality and performance as those made from primary aluminum.

- Closed-Loop System:

- Recycling aluminum creates a closed-loop system where the material can be continuously reused and repurposed.

- This circular economy approach minimizes waste and maximizes the utilization of resources.

- Reduced Land Use:

- Bauxite mining requires significant land use, often in sensitive or pristine areas.

- Recycling aluminum reduces the demand for new mining operations and land disturbance.

Also Read: RECYCLING MILK CARTONS AND PROPER DISPOSAL OF PAPER CARTONS

How to recycle aluminum cans

Recycling aluminum cans is a straightforward and environmentally responsible practice. Here’s a step-by-step guide on how to recycle aluminum cans effectively:

- Collect Aluminum Cans:

- Start by collecting aluminum cans from various sources. You can gather cans from your own household, friends, neighbors, local businesses, public buildings, or events.

- Clean the Cans:

- Rinse the cans to remove any leftover beverages or residues. Clean cans help maintain the recycling process’s efficiency.

- Separate Aluminum from Other Materials:

- Ensure that aluminum cans are separated from other recyclables like plastic, glass, and paper. Most recycling programs prefer source-separated materials to ease the sorting process.

- Locate Recycling Centers:

- Find local recycling centers that accept aluminum cans. You can do this through an online search, consulting the yellow pages of your phone book, or contacting local government offices for assistance.

- Transport to Recycling Center:

- Once you’ve collected a significant quantity of aluminum cans, transport them to the nearest recycling center. Some centers may offer drop-off locations or provide curbside pickup services.

- Weigh and Sort the Cans:

- At the recycling center, you may be required to weigh and sort your aluminum cans. Follow the guidelines provided by the center to facilitate the recycling process.

- Receive Compensation (If Applicable):

- Many recycling centers pay for aluminum cans based on their weight. You may receive compensation for the cans you bring in, which can vary depending on market prices.

- Support Recycling Programs:

- By recycling aluminum cans, you contribute to local recycling programs and help divert waste from landfills. Your efforts support sustainability initiatives in your community.

Interesting Facts about Amuminum Recycling

Aluminum is a true champion in recycling. Unlike some materials that degrade during recycling, aluminum can be recycled indefinitely without losing its quality or purity. It can be melted down and reused repeatedly, making it a sustainable and efficient material.

Recycling aluminum saves an impressive amount of energy. In fact, it saves up to 95% of the energy needed to produce aluminum from raw bauxite ore.

FAQs about Aluminum Recycling:

1. Why is aluminum recycling important?

- Aluminum recycling is crucial because it conserves natural resources, reduces energy consumption, lowers greenhouse gas emissions, and minimizes waste in landfills. It contributes to a more sustainable and environmentally friendly future.

2. How is aluminum recycled?

- The aluminum recycling process involves collecting, sorting, cleaning, and melting aluminum cans and other aluminum products. The melted aluminum is then cast into new products or used to manufacture aluminum sheets.

3. What types of aluminum can be recycled?

- Aluminum cans, such as soda cans and food containers, are commonly recycled. Additionally, aluminum products like foil, gutters, and window frames can also be recycled.

4. Should I remove labels and flatten aluminum cans before recycling?

- You don’t need to remove labels or flatten aluminum cans before recycling. Simply rinse them to remove any leftover contents, and they are ready for recycling.

5. Can I mix aluminum cans with other recyclables like paper and plastic?

- While some recycling programs accept mixed recyclables, it’s generally recommended to separate aluminum cans from other materials for efficient recycling. Source-separated materials are easier to process.

6. Do I get paid for recycling aluminum?

- Many recycling centers pay for aluminum based on its weight and current market prices. The compensation you receive may vary depending on the recycling center and market conditions.

7. How many times can aluminum be recycled?

- Aluminum is highly recyclable and can be recycled indefinitely. It doesn’t degrade during recycling, so it can be melted down and reprocessed repeatedly without losing its quality.

8. Where can I find a recycling center for aluminum?

- You can locate recycling centers that accept aluminum by doing an online search, checking your phone book’s yellow pages, or contacting local government offices for assistance.

9. What happens to recycled aluminum?

- Recycled aluminum is melted down and can be used to create new aluminum products or sheets. It can also be used in various industries, including automotive and construction.

You May Also Like